Constructing stuff with metal is not as difficult as you may think. Thanks to V-slot and T-slot aluminum extrusions, now it’s easy to form structural frames. To know how to work with aluminum, first, you need to understand what it is and how to get started with the material to build something awesome.

What Is Aluminum Extrusion?

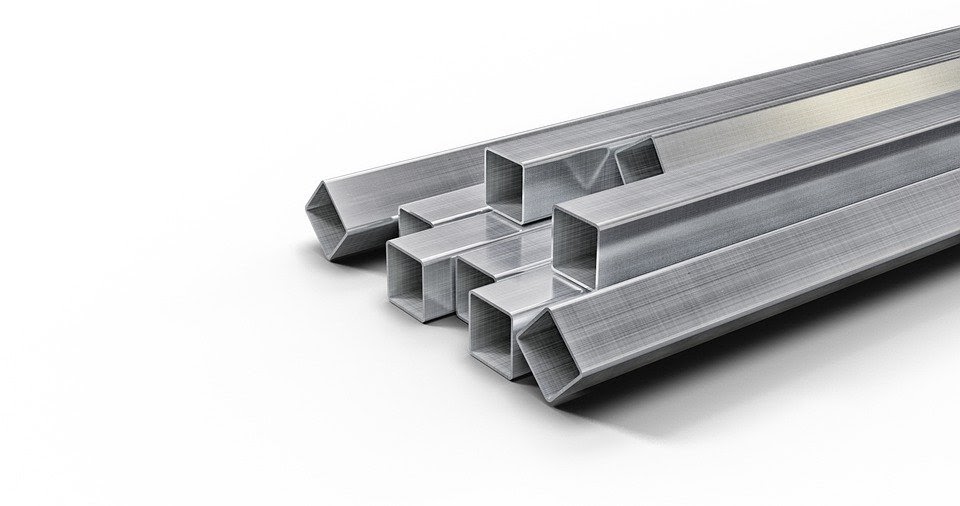

Basically, aluminum extrusions are aluminum that’s extruded through a shaped opening which is called a ‘die’. Same as how plastics are produced, hot metal is pressed through a shaped opening that forms a usable product. These extrusions have many advantages and are widely used.

Extruded aluminum is actually lighter, stronger, and uses less amount of material (which means it’s cheaper) compared to its solid counterparts. Extrusions come in different shapes, so a certain variation appropriate for your case of use can frequently be found. Ultimately, aluminum is simple to work with and you need to use only basic tools. It’s usually unsuitable for industrial-strength applications, but you might be surprised at everything that can be built from it.

This article will focus on V-Slot aluminum extrusion, so read below to find out how to work with it.

V-Slot Versus T-Slot

There are a variety of extrusion shapes available today. However, there are two main profiles that can be of use for your project, and that’s V-Slot and T-Slot. T-Slot aluminum has a T-shaped furrow on both sides. On the other hand, V-Slot is similar, but it has slightly beveled edges.

Although that might seem like just a little difference, it has a major impact on their use. V-Slot enables wheels and bearings to seat inside the profile itself, meaning it’s able to double as a linear rail, significantly minimizing the cost of parts for control of movement.

Both are somehow similar, however, it’s often best to work with one kind per project. Basic elements such as brackets and T-Nuts work well with either. But, slightly more specific parts like bearings or uncommon joints might only work with one or the other.

Dimensions

V-Slot comes in various sizes, and the range is broadening. It comes in different lengths, and some vendors may even cut to length.

The most commonly used sizes are: 20mm x 20mm, 20mm x 40mm, 20mm x 60mm and 20mm x 80mm. Even the pieces with the smallest diameter are extremely strong, and the biggest pieces are fully capable of heavy-duty use cases.

Cutting And Working

You may cut the V-slot in different ways. Manufacturers say it can be cut the same as timber (using a chop saw), but that’s not highly recommended. You can dull your blade very easily by doing that. So, if you don’t have a special blade for metal cutting, it might also not produce a nice finish.

The easiest way to cut V-slot aluminum is to use a hacksaw. Use a machinist square to mark a precise line, then secure it to a proper workbench and slowly cut it. Don’t try using a junior hacksaw (even for small dimensions) since they are often a waste of time. Any rough edges or out-of-line cuts can be fixed with a file tool.

Final Touches

You can buy V-Slot with two finishes – untreated and black. Untreated is just the aluminum as it is, while the black it’s anodized through a chemical process that reacts with the exterior of the aluminum.

Whereas the black one looks much cooler, it’s far easier to damage or mark. Plus, untreated aluminum allows you to anodize in various colors at a later stage. The paint is not fitting, neither is powder coating. That’s because both of them include a layer of paint outside the aluminum which minimizes the potency of the bearings.

Connecting Pieces

Connecting parts together is very simple. The most common technique is through T-Nuts. These are placed into the slots of the aluminum, and allow a bolt to be constrained against them. They are pretty cheap, although it can sometimes be complex to align several ones correctly.

If you want to spend less, you can 3D print your own connector parts. Otherwise, metal brackets from a hardware shop can usually be bought very cheaply. Since these come in various sizes, it’s a good idea to write down some measurements before buying brackets of adequate size.

Using the brackets is very simple, slip two (or several) T-Nuts into the slots of the extrusion. Then, line up your bracket, and bolt it by using adequate size bolts. Use the same technique for connecting different pieces of V-slot extrusions.

Final Words

If you are planning on building something with V-slot aluminum extrusion, we hope our guide helps you to get prepared and start with your project easily.