Ever since the world of technology came about, the world has never been the same.

And while various developments helped this come about, one of the most important was that of PCBs.

PCBs, or Printed Circuit Boards, are by far one of the most revolutionary technological developments to have ever come about.

A great innovation that helped to replace wires to a large extent, they have found their way into everything from toys and lighting to computers and even aircrafts.

Indeed, the principles are something which has been widely used for just about every known application imaginable.

There is much that can be said about aluminum PCBs.

Given in the points below, are some of the key features about these interesting varieties of PCBs.

-

Basic Structure & Design

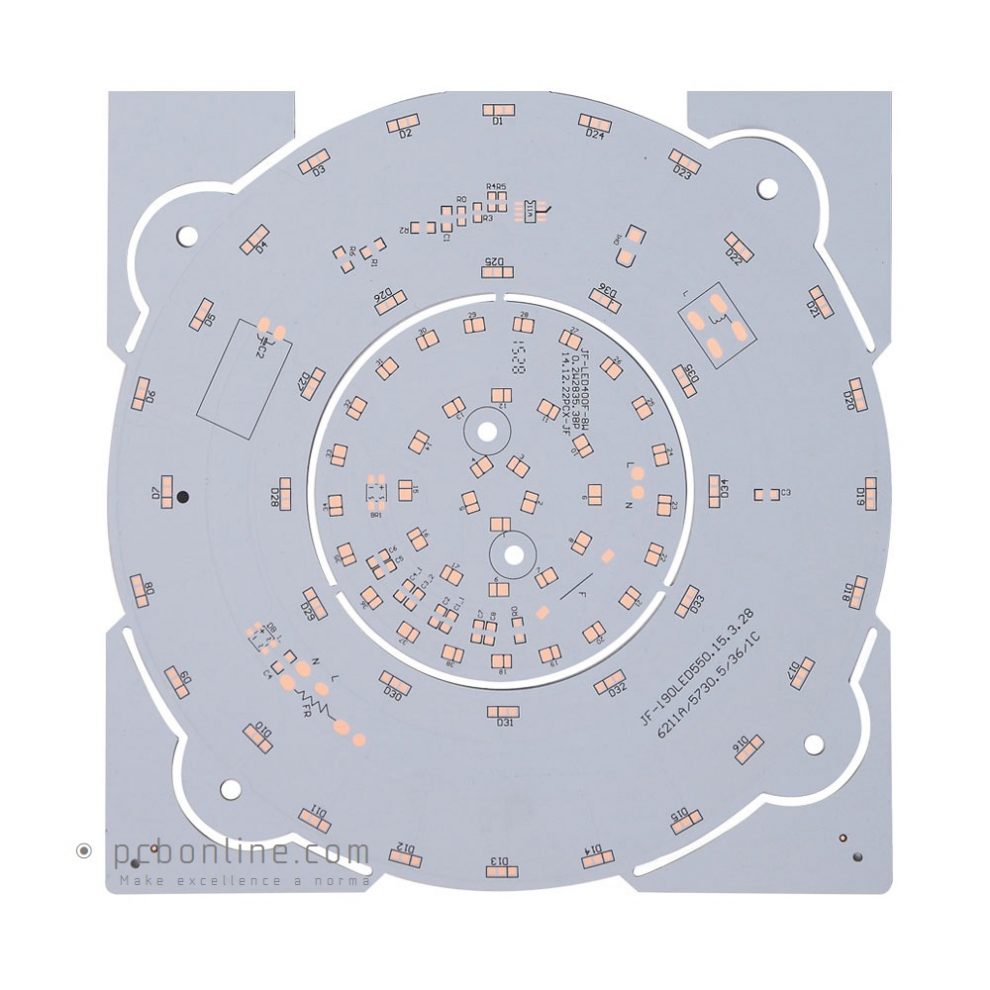

As the name would suggest, aluminum PCBs are those boards, which are made with the main component being aluminum.

Also called aluminum clad or aluminum base boards, they are comprised of three layers in general, namely that of aluminum, a dielectric material and copper. In addition to this, certain designs may come with two aluminum layers rather than one, with the base being the aluminum ‘membrane’ layer and the layer on top of it being the aluminum ‘base’.

The base of the board is designed using aluminum, and serves as the substrate and the foundation on which the rest of the components are placed. The next layer of the PCB is that of the dielectric materials, which serves as a thermally conducting but electrically insulating layer of the PCB.

The dielectric layer is comprised of materials which allow for heat to be transferred from the copper layer to the aluminum one, without affecting the flow of electricity in the board. It is the layer which acts as a ‘heat sink’ for the circuitry, removing the same before it can cause any harm to the circuits.

The topmost layer of the board is that made using copper, although other materials may also be used. This is the circuit layer, which is used for all the circuitry work on the PCB, responsible for the carrying of signals, data, and electricity and so on. The layer in turn, can either be printed, etched, etc, just like in the case of any other PCB.

In addition to this, some aluminum PCBs may also come with an added solder mask, located on top of the copper layer. The solder mask serves as a protective layer, which prevents the underlying copper assemblies from corroding or otherwise getting damaged. This serves to add longevity to the circuitry, and prolong the life of the PCBs.

A variant of PCBs in turn, is a hybrid design, where the substrate is designed, not using aluminum in its entirety, but rather a mix of aluminum and a non-thermal material. Commonly called Hybrid Aluminum PCBs, they are used for their ability to allow for the substrate to be thermally conducive, while at the same time reducing manufacturing costs of the same.

-

Benefits

There are several benefits to the use of aluminum PCBs, which is why they are widely used across the industry.

- Heat Dissipation: One of the biggest advantages of aluminum PCBs however, is that of their ability to dissipate heat. There is a great deal of heat generation in many applications, which necessitates the requirement for rapid heat dissipation.

This is where aluminum PCBs can come into the picture. Aluminum, being a good conductor of heat, allows for the rapid dissipation and removal of heat from the assemblies, thereby increasing its efficiency and longevity.

The ability to remove heat from the assemblies are especially valued in many applications, given that the presence of the same can lead to malfunction or even damage to the components, and indeed the entire device.

- Durability: Given that the PCBs are designed and built upon a solid metal substrate, they are ideal and durable in comparison to PCBs designed using materials such as ceramics.

- Costs: Although manufacturing cost of aluminum PCBs are on the higher end, the material costs are fairly affordable. Given that the base layer, aluminum is available in high abundance, raw material costs are fairly affordable.

- Lightweight: Aluminum by nature is a very light material, which is the reason it is used in applications such as aircrafts.

The same advantage of being light-weight however, can also translate to that of PCBs as well, where the relatively low weight of aluminum can prove to be very useful in creating lightweight electronics and other components.

-

Disadvantages

As much as aluminum PCBs has their advantages, they do come with some downsides as well.

- Cost: One of the biggest downsides of the same has to do with their overall cost, largely with regard to their manufacture. The material costs however, are relatively affordable, given that aluminum is available in abundance.

- Design Limitations: Then there are the issues related to the design itself. Currently, most aluminum PCBs are single sided, meaning that they carry circuits only on one side of the board.

This means that in applications where circuitry is required on both sides of the PCBs, it can be difficult to find suitable aluminum PCBs. While it is possible to create dual-sided PCBs with aluminum as a substrate, the industry is largely focused on the use of other PCB variants rather than aluminum ones.

-

Variants

Aluminum PCBs can be in one of two varieties, namely fixed and flexible.

For the most part, the ones that is most common is that of fixed PCBs, with the majority of them being fixed in nature.

At the same time however, there is the presence of PCBs which are flexible as well, designed for applications where flexible circuits are required, as in the case of moving machinery and other such electronic components.

Regardless, they have proven themselves to be effective in both fields of application.

-

Applications

As already explained, the main reason for the use of aluminum PCBs, is for the heat-dissipation advantages offered.

This means that one can find aluminum PCBs being used wherever heat is a problem, and requires for the same to be rapidly dissipated.

Some common applications where aluminum PCBs can be found are high-current circuitry, automotives, power supplies, automotive applications, motor controllers, etc.

To sum up, there is a lot more that can be said about these PCB variants, than what has been explained and listed out above.

The above aspects however, are some of the key features about aluminum PCBs among the many other details about the same.

Add Comment