As the digital age continues, automation technologies are quickly taking the workplace by storm. And their impact on businesses is enormous. That’s why you should take advantage of the opportunities presented by technological advancements.

However, small business owners may feel like such technology is just a luxury they do not need. This is where they are wrong. Any company, big or small, can benefit from robotic technology.

The robots are coming

Automation technology, such as robotic machines that use artificial intelligence (AI) software, is the future of the manufacturing, medical, and other industries. In fact, it is expected that it will replace a huge chunk of the human workforce in the future. Experts even predict that by 2030, about 38% of jobs in the United States economy will be occupied by robots, making it a more cost-effective business solution.

However, many people think that only large corporations will benefit from this technological innovation. It’s true that large enterprises are in the best position to reap the rewards of automation technology. But that doesn’t mean small business can’t have a slice of the pie—so to speak.

The only difference between a large and small business is that large enterprises are ready to take on the challenge. Small business owners, on the other hand, are still hesitant because they don’t know how to utilize this technology to their advantage. They may even see it as an extra cost. But with reduced manpower, you will get to save on wages in the long run.

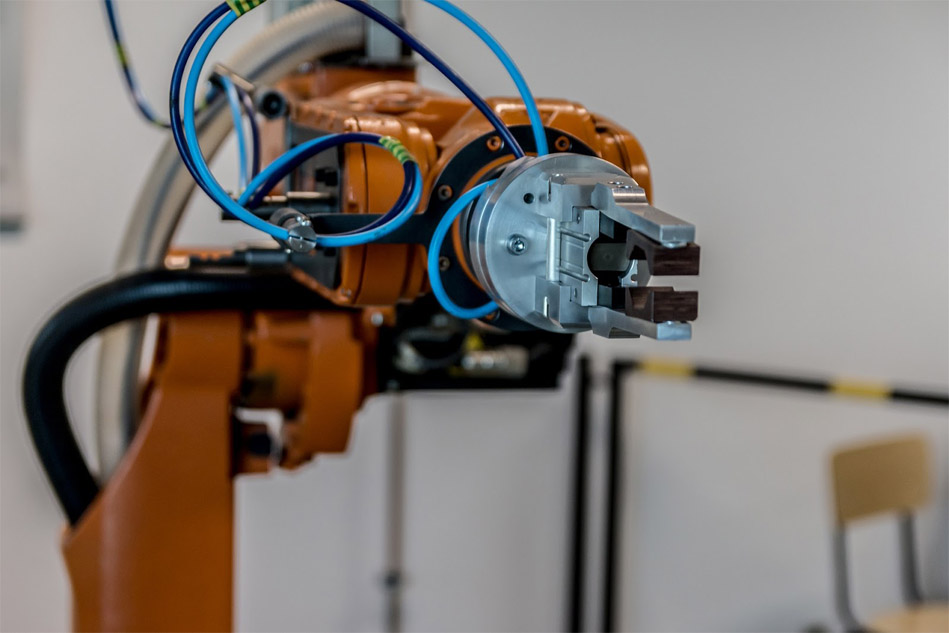

How servos improved flexibility of machines and robots

The MITO automatic shrink-wrapping machine of MIMI s.r.l., one of Italy’s leading manufacturers of machinery for packaging, is designed specifically for the wrapping of various pack sizes and configurations of cartons, bottles, tubs, or cans.

Control Techniques worked closely with MIMI to incorporate MITO with highly synchronized and accurate servo drives in its three crucial areas: film cutting, throughput speed, and wrapping action control. This has resulted in a significant increase in the versatility and throughput of the machine.

Digital vs Analog Servo Drives

Visually, it’s very hard to differentiate between an analog and digital servo drive. The only way to tell them apart is through the way they process and signal information.

Analog servos mainly operate on voltage signals that come from the pulse width modulation (PWM). The PWM is essentially off when an analog servo is at rest. This makes reaction sluggish as it turns on when action is placed on it, making it not suitable for advanced applications.

Digital servos, on the other hand, make use of a small microprocessor to direct and receive action at high-frequency voltage pulses. This allows them to send faster pulses that help provide consistent torque. As a result, you get a smoother and quicker response time.

Robots are changing the workplace

Automation will, without a doubt, change everything we know about running a business—from the manufacturing, transportation, and storage industries to the medical industry. Gone are the days when manual labor is the only option for businesses. Now, with the help of technology, mass production is more efficient than ever.

Aside from implementing automation technology, here is an example of using numerical control for machines part production.

Robotics has also proven quite useful to the medical industry, where surgical robots are used for minimally invasive surgery, remote surgery, and unmanned surgery. And with the accuracy and precision of robotic surgery, it is perfect for making smaller incisions and miniaturization—resulting in less pain, reduced blood loss, and faster healing time.

Workplace automation

The manufacturing industry, in particular, can make the most of this technology because of all the big and repetitive work that needs to be done. As of today, these are the different manufacturing environments and processes being used—which can all benefit from robotic technology.

Some other benefits you get to enjoy with workplace automation include:

- Safer working environment

- Reduced potential for human error

- Increased productivity

- Cost savings in the long run

Servo Drives For Robotics Applications

Automation technology is the game changer we need to help grow businesses. It also helps make our lives easier, as it increases warehouse materials handling throughput and enables the discovery of new non-invasive surgical practices. Small manufacturing companies can also benefit from the use of collaborative robots.

However, do take note that even in robotics technology, there are still things to consider—such as not all servo drives are created the same.

For example, heat dissipation needs to be under control when working on automation projects that need tight integration of the electronics with the robot’s actuation. On the other hand, latency and deterministic coordination allow precise and smooth motion when working with multi-axis robots.

Add Comment